BIDATEK WATER SOLUTIONS offers a wide range of treatment plants aimed at obtaining water for human consumption, irrigation and farming. The plants are designed using different technologies for the elimination of the different pollutants present in the raw water and reach the quality standards set by local authorities and the WHO (World Health Organization).

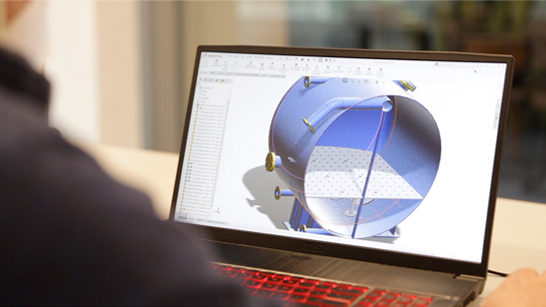

The whole plant is manufactured based on standard 20 or 40 feet containers.

DECANTATION AND FILTRATION TECHNOLOGY

The water treatment plants equipped with decantation and filtration technology, known as conventional technology, are specially suitable for surface waters (rivers, lakes and reservoirs) as well as for the treatment of groundwater or wells that require the removal of specific contaminants (iron, manganese, arsenic, etc.).

These plants are equipped with different water purification processes such as sieving, oxidation, coagulation, decantation, sand filtration, active carbon, disinfection, etc. And whole treatment are manufactured based on standard 20 or 40 feet containers.

equipped with the following treatments:

- Pumping: from the collection point to the plant.

- First roughing: first removal of coarse and floating particles through hydrocyclone, sieves etc.

- Oxidation: for bacteria elimination and soluble metal ions precipitation (As, Mn, Fe, etc.).

- Dosing of reagents: such as oxidizing compounds for pre-disinfection and coagulants for precipitation of colloids and formation of flocs.

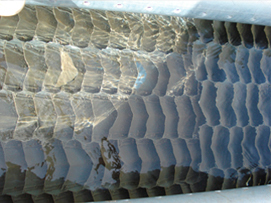

- Lamella decanting: Sedimentation of flocs formed in the previous stage.

- Filtration: sand, AFM and activated carbon filtration to reach the final quality.

- Post-treatment: chlorination by chlorine gas or hypochlorite.

BENEFITS

have the following benefit for their users:

- High quality water: drinking water complying with WHO specifications (World Health Organization) or customer’s higher requirements.

- Easy to transport by its container structure.

- Minimum civil works: only small ditches and foundations.

- Easy and quick, assembly, all its elements are inside the containerised structure.

- Easy commissioning: preassembled plant.

- Easy operation: reliable technologies and easy operation.

- Centralized operation: Electric control cabinet in the container structure.

- Robust maintenance: High quality equipment.

- Mobile: possibility of relocating the packaged plant.

TREATED WATER QUALITY

plant meets the following minimum quality levels:

- Turbidity: < 5 NTU

- Color: < 15 TCU

- Taste and Smell: nonexistent

- pH: 6,5-8,5

- Residual chlorine (mg / l): 1-2 mg/l after 30 minutes contact

- Faecal coliforms: 0 UFC/100 ml

- Total coliforms: 0 UFC/100 ml

CUSTOMIZED SOLUTIONS

following models according to their treatment capacity:

| MODEL BDTKGIP-5 BDTKGIP-25 BDTKGIP-50 BDTKGIP-100 BDTKGIP-200 BDTKGIP-400 |

FLOW (m3 / h) 5 25 50 100 200 400 |

NUMBER OF CONTAINERS 1 de 20 ft 2 de 20 ft 1 de 40 ft 2 de 40 ft + 1 de 20 ft 3 de 40 ft + 2 de 20 ft 6 de 40 ft + 4 de 20 ft |

Av. Alcalde José Elosegui, 43

Donostia-San Sebastián 20013

Gipuzkoa – SPAIN